Bambu Lab P1S: Not a Laser Cutter, But a 3D Printing Beast!Lately, guys, there’s been a bit of a buzz, and frankly, some understandable confusion swirling around the

Bambu Lab P1S

and whether it’s some kind of

laser cutter

. Let’s get one thing straight right off the bat: the

Bambu Lab P1S is not a laser cutter

. It’s an incredibly powerful, fast, and feature-packed 3D printer that has absolutely

rocked

the additive manufacturing world. We’re talking about a game-changer for hobbyists and professionals alike, bringing high-speed, high-quality 3D printing to the masses in a way few others have managed. This article is all about clearing up that common misconception, diving deep into what the P1S actually

is

, what true laser cutters do, and why this confusion might be happening. So, if you’ve been scratching your head wondering if your Bambu Lab P1S can etch or cut materials with a laser, stick around, because we’re about to unravel the mystery and shine a light on what makes this machine so special in its

true

domain: 3D printing. We’ll explore its incredible capabilities, compare it to actual laser cutting technology, and even guide you towards real laser cutting solutions if that’s what you’re truly after. Our goal here is to provide crystal-clear, valuable information to ensure you’re using the right tool for the job, whether that’s fabricating intricate plastic parts or precision-cutting wood and acrylic. Let’s embark on this journey to understand the

Bambu Lab P1S

in its rightful context – as an engineering marvel in the world of

3D printing

, and not as a

laser cutter

. Don’t worry, by the end of this, you’ll be an expert on differentiating these fantastic technologies!## Unpacking the Confusion: Is the Bambu Lab P1S a Laser Cutter?Alright, let’s tackle this head-on, because the

Bambu Lab P1S laser cutter

query is something we’re seeing a lot. It’s crucial to understand that despite its enclosed, high-tech appearance and its place in the broader digital fabrication ecosystem, the

Bambu Lab P1S

is unequivocally a

3D printer

, and it does

not

possess any laser cutting capabilities. When we talk about the

Bambu Lab P1S

, we are talking about a machine designed from the ground up to create three-dimensional objects by adding successive layers of material, typically plastic filament. This process is known as

additive manufacturing

, which is the core principle of

3D printing

. A laser cutter, on the other hand, operates on an entirely different principle; it uses a focused high-power laser beam to cut, engrave, or etch materials by

removing

material through melting, burning, or vaporization – a

subtractive

manufacturing process. This fundamental difference is key to understanding why the P1S, for all its incredible technological advancements, simply isn’t built for laser operations.The confusion likely stems from a few places. First, both 3D printers and laser cutters often reside in similar environments – makerspaces, workshops, and creative studios. They are both tools of digital fabrication, taking digital designs and turning them into physical objects. They both often feature sleek, enclosed designs, sometimes with similar-looking safety features like smoke extraction or viewing windows. For someone new to the world of advanced manufacturing, or perhaps only familiar with older, more rudimentary desktop 3D printers, seeing a sophisticated machine like the

Bambu Lab P1S

with its enclosed chamber and various high-tech components might lead to an assumption that it’s capable of a wide range of tasks, including laser cutting. Moreover, some 3D printers

do

offer optional add-ons for low-power laser engraving, but this is typically a specific, often less powerful, module that is explicitly advertised as such and is rarely capable of true cutting. The

Bambu Lab P1S

does not offer any such integrated or optional laser module for cutting or engraving. Its core function, its entire design, and its operational mechanisms are dedicated solely to the precise extrusion and layering of plastic filament. Think of it this way: a car and a motorcycle both have engines and wheels and get you from A to B, but they are fundamentally different vehicles designed for different experiences. Similarly, a 3D printer and a laser cutter are both fantastic fabrication tools, but their underlying technology and purpose are distinct. So, to firmly put this myth to rest, if you’re looking to cut or engrave materials like wood, acrylic, or leather with a laser, the

Bambu Lab P1S

is not the tool you need. It excels at creating complex 3D shapes from plastic, and that’s where its magic truly lies. We’ll explore that magic next!## What Exactly is the Bambu Lab P1S? A Deep Dive into its 3D Printing ProwessAlright, now that we’ve unequivocally established that the

Bambu Lab P1S

is

not

a laser cutter, let’s talk about what it

is

: an absolute beast of a 3D printer! This machine, part of Bambu Lab’s revolutionary lineup, has seriously shaken up the desktop 3D printing scene, delivering features and performance that were once the exclusive domain of much more expensive, industrial-grade machines. The

Bambu Lab P1S

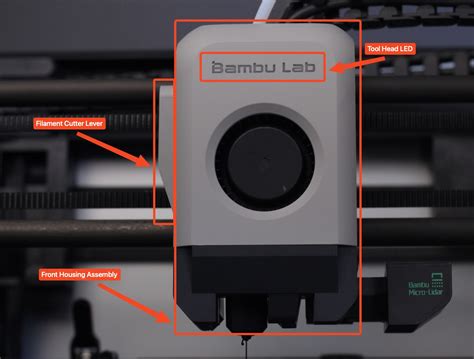

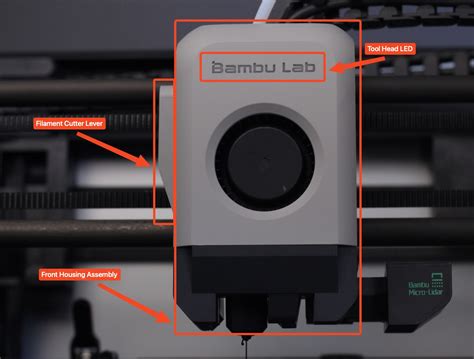

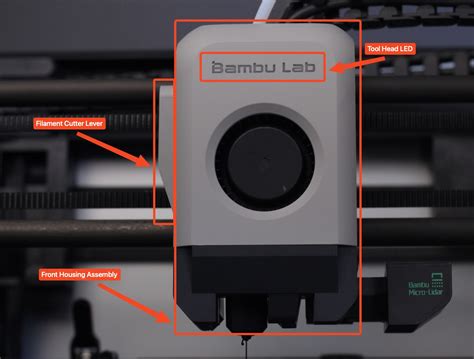

is a core-XY FDM (Fused Deposition Modeling) 3D printer, meaning it builds objects by extruding molten plastic filament layer by layer. But it does this with a level of speed, precision, and reliability that has frankly astonished the community.One of the most talked-about features of the

P1S

, and indeed the Bambu Lab ecosystem, is its incredible

speed

. We’re talking print speeds that are significantly faster than many competitors, often cutting print times in half or even more for complex parts. This isn’t just about raw motor speed; it’s a combination of advanced kinematics, a lightweight toolhead, and sophisticated motion control algorithms that allow it to accelerate, decelerate, and change direction with astonishing agility. This means less waiting around for your prints to finish, which is a massive win for productivity and getting those creative ideas into physical form faster.Beyond speed, the

P1S

truly shines with its

reliability and user-friendliness

. Out of the box, these machines are known for just

working

. They come highly pre-calibrated and feature automatic bed leveling, vibration compensation, and even flow calibration, making the setup process incredibly smooth. This takes away a lot of the common headaches associated with 3D printing, especially for beginners or those who just want to hit print and walk away. The fully enclosed chamber of the

P1S

is another significant advantage, especially when working with engineering filaments like ABS, ASA, or Nylon. This enclosure helps maintain a stable internal temperature, reducing warping and improving layer adhesion, leading to higher quality and more reliable prints. It also helps contain any odors from certain filaments and reduces noise, making it a more pleasant experience overall.But here’s where the

Bambu Lab P1S

truly stands out from many other printers in its class: its compatibility with the

Automatic Material System (AMS)

. Guys, this is a game-changer for multi-material and multi-color printing. The AMS unit, which can be purchased separately, allows the P1S to automatically switch between up to four different spools of filament during a single print. This means you can print objects with multiple colors or combine different material types (e.g., a strong base with flexible supports) without any manual intervention. For anyone looking to add a vibrant, professional touch to their 3D prints, the AMS is an absolute must-have accessory that elevates the

P1S

from a great printer to an

exceptional

one. It supports a wide range of filaments including PLA, PETG, TPU, ABS, ASA, and more, offering incredible versatility. The build volume is a respectable 256x256x256mm, providing ample space for most common projects. With features like a direct-drive extruder, hardened steel nozzles for abrasive materials, and a robust all-metal frame, the

Bambu Lab P1S

is built for performance and longevity. It integrates seamlessly with Bambu Studio software for slicing and features cloud connectivity for remote monitoring and control, making it a truly modern and connected printing experience. So, to reiterate, while the

Bambu Lab P1S

might look like a futuristic piece of tech, it’s all about putting incredible 3D prints in your hands, quickly and reliably. It’s a testament to innovation in additive manufacturing, making advanced 3D printing accessible and enjoyable for everyone.## Demystifying Laser Cutters: What They Are and How They WorkOkay, since we’ve cleared up the fact that the Bambu Lab P1S is a 3D printer, let’s shift our focus to understanding what a true

laser cutter

actually is. If you’re here because you genuinely need a tool for cutting or engraving, this section is for you, guys! A

laser cutter

is a powerful and precise machine that uses a highly focused beam of light – a laser – to cut, engrave, or mark various materials. Unlike 3D printers that

add

material, laser cutters are a form of

subtractive manufacturing

, meaning they

remove

material to create a desired shape or design.The fundamental principle behind a

laser cutter

is pretty cool: a high-power laser beam is generated, often by a CO2 tube, a diode, or a fiber optic source, depending on the type of machine. This beam is then directed through a series of mirrors and focused by a lens onto the surface of the material being processed. The immense concentration of energy at this tiny focal point causes the material to rapidly heat up, melt, vaporize, or burn away, creating a clean cut or an etched mark. The entire process is controlled by computer numerical control (CNC), meaning you design your part in software, and the machine executes the path with incredible accuracy.There are primarily three main types of

laser cutters

you’ll encounter, each suited for different applications and materials:1.

CO2 Lasers

: These are the most common type for hobbyists and small businesses.

CO2 laser cutters

use a gas mixture (primarily carbon dioxide) to generate the laser beam. They are excellent for cutting and engraving a wide array of organic and non-metallic materials like wood, acrylic, paper, leather, fabric, and rubber. They can also engrave on certain coated metals, glass, and stone. However, they generally cannot cut bare metals. These machines come in various power levels, from small desktop units to large industrial machines. Their versatility for common workshop materials makes them a popular choice.2.

Diode Lasers

: Newer to the scene and rapidly gaining popularity,

diode laser cutters

use powerful semiconductor diodes to produce the laser beam. They are typically more compact, energy-efficient, and less expensive than CO2 lasers, making them very appealing for home users and beginners.

Diode lasers

excel at engraving on a wide range of materials including wood, leather, some plastics, and even some metals (though usually for engraving, not cutting). They can also cut thinner wood, acrylic (especially opaque colors, clear acrylic can be tricky), and paper. Their power is generally lower than CO2 lasers, so cutting thick materials can be slower or require multiple passes, and their material compatibility is somewhat more limited.3.

Fiber Lasers

: These are industrial-grade machines that use an optical fiber doped with rare-earth elements as the laser medium.

Fiber laser cutters

produce a much smaller focal spot and a significantly higher power density, making them ideal for cutting and marking metals (steel, aluminum, brass, copper) with incredible precision and speed. They can also engrave on plastics and ceramics. While highly efficient and capable for metalwork,

fiber lasers

are typically much more expensive and complex, putting them out of reach for most hobbyists, but they are the go-to for serious metal fabrication.The applications of

laser cutters

are vast and diverse. Think about custom signage, intricate architectural models, personalized gifts, fashion and textile design, creating prototypes, or even artistic pieces. From cutting precise components for electronics enclosures out of acrylic to engraving elaborate designs into a wooden coaster, a

laser cutter

opens up a whole new realm of creative and manufacturing possibilities that are distinctly different from what a 3D printer offers. Understanding these differences is key to choosing the right tool for your project. A

laser cutter

is all about precision cutting and engraving on flat stock materials, transforming sheets into intricate designs or parts, a job the

Bambu Lab P1S

simply isn’t designed to do.## Why the Mix-Up? Understanding the Source of the